Innovagel® Advanced Softgel Technologies

These advanced technologies allow us to deliver turnkey softgels for the nutritional market that include sensitive oil mixtures and difficult formulations such as viscous suspensions with up to 50 % solids and hydrophilic ingredients.

The main technology groups are:

lnnovagel® enclosed blending vessels allow the manufacture of fill material under vacuum conditions in conjunction with inert gas blanketing to protect oxygen sensitive ingredients such as Omega-3 fish oils and reducing reject rate due to contamination and environmental exposure. For suspensions, powerful milling equipment is used to obtain consistent and homogenous blends to maintain uniformity and prevent defects throughout the encapsulation process.

Innovagel® automated gelatin-melting vessels are designed to reduce the set-up for more efficient processing. Large capacity, automated processing and viscosity controls reduce variability and assure consistent high quality of the gelatin shell.

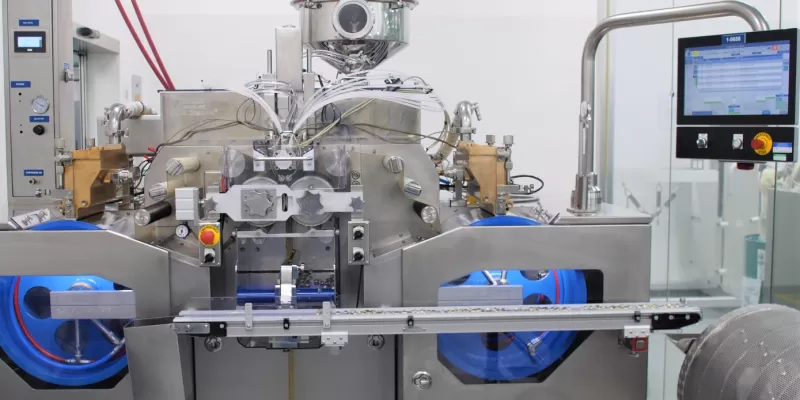

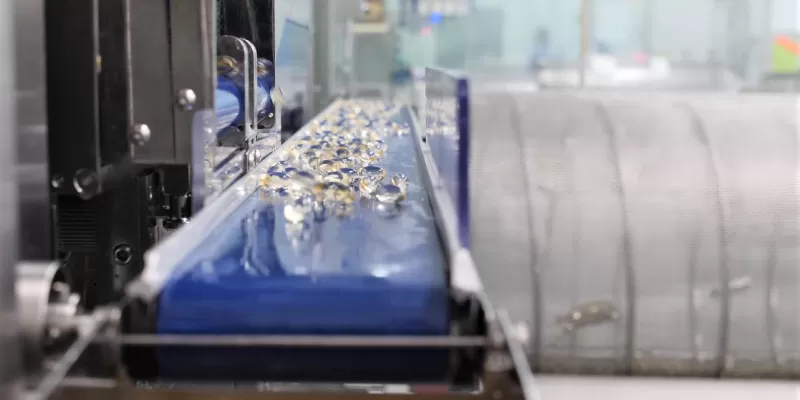

Innovagel® encapsulation processing equipment uses high quality softgel machines from Canada and Japan, with customization performed in Switzerland. From size 2 oval to size 28 oblong, we can deliver a full range of sizes and shapes to serve your needs. We have twist-offs and cut-offs and will work with you in making custom dies if desired. Additionally, lnnovagel® high speed imprinting as weil as laser etching machines can help to brand your softgels.

Innovagel® continuous drying system uses individual tumbler baskets that provides a more consistent overall product. This continuous drying system is more efficient and two times faster than tray drying. Large room with several tumbler baskets provides multiple drying batches at the same time.

Innovagel® finished packaging process is a newly renovated and semi-automated packaging suite. The packaging process is a modular, linear flow packaging line with thirteen different machines in place with the capability to pack multiple bottle sizes in various packaging configurations.