Purification Technologies

At KD Pharma Group we use multiple patent-protected, state-of-the-art separation and purification technologies

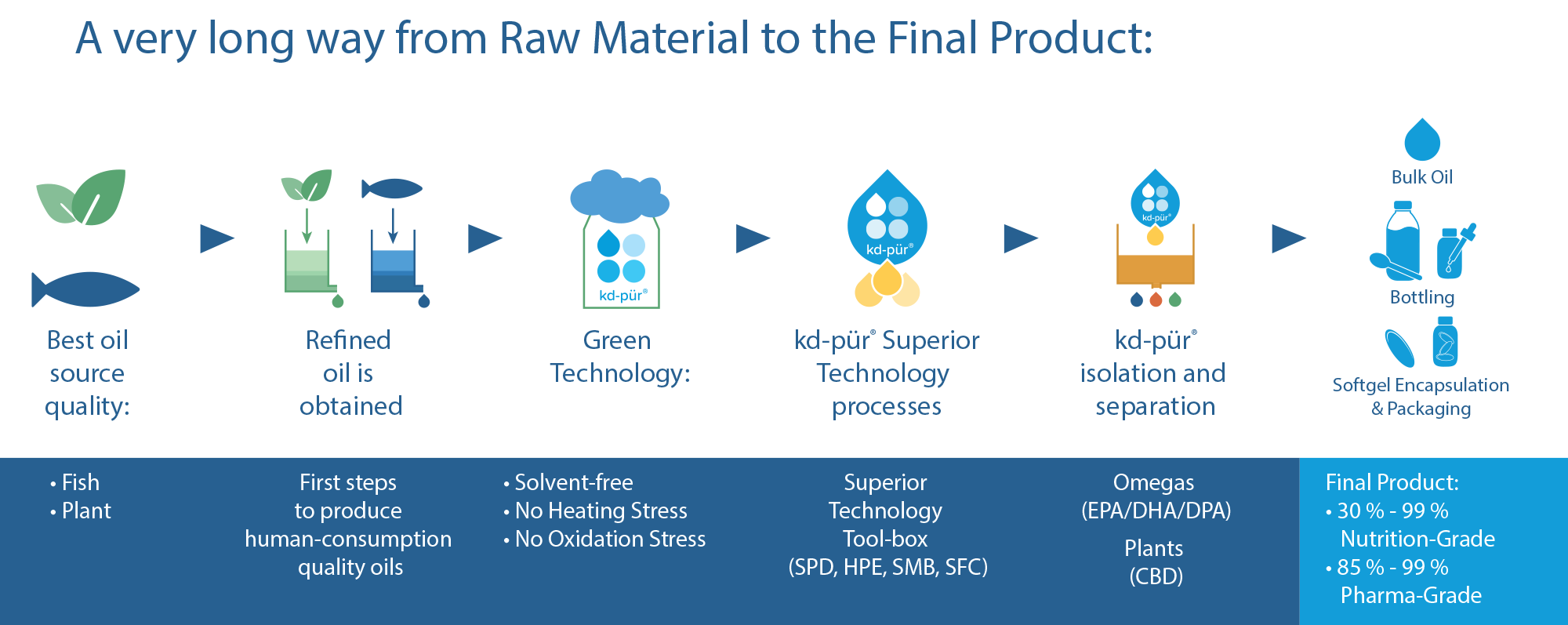

These technologies allow for the production of Omega-3 fish and algae oils, among other lipids extracts, that is unsurpassed in quality and purity, and can achieve concentrations as high as 99 % of a single fatty acid or phytochemical.

The main technology groups include:

kd-pür® Supercritical Fluid Chromatography (SFC). In the SFC process, the oil coming from the SFE process (Supercritical Fluid Extraction) is passed through a chromatographic column which is packed with a highly selective separation material. While passing through this column, the fatty acids and lipid mediators get separated according to their size and degree of unsaturation. This allows the individual fractions, each enriched with specific Omega-3’s or phytochemicals, to leave the column at separated intervals. Finally, the CO2 is released from the oil and recycled, allowing for an exceptionally high level of purity for the Omega-3 concentrates and plant extracts.

Unlike some other extraction methods, with kd-pür® technology, no chemical solvents, water, sugar, saturated fatty acids, cholesterol or proteins can be found in the finished oil.

kd-pür® Enhanced Silver Technology is a further development of the kd-pür® technology, where ultra-high concentrations of EPA, DHA, DPA and other specific Omega-3 components can be achieved. This technology uses the supercritical carbon dioxide method and also includes a silver-based extraction process.

With this technology, natural oils can be extracted to previously unheard-of levels of purity. Ultra-high levels of Omega-3 such as EPA, DHA, DPA, Omega-6, Omega-7, Omega-9 are made into very pure concentrates. Impurities are minimized to extremely low levels.

Kd-pür® Simulated Moving Bed Technology (SMB) is a highly engineered process for implementing chromatographic separation. It is used to separate one chemical compound or one class of chemical compounds from one or more other compounds based on their geometry and has advantages over using simple (batch) HPLC chromatography.

The technology allows the production of large quantities of highly purified material at a continuous and high rate of production, and decreases solvent and energy requirements. When combined with other KD Pharma technologies, SMB can produce extremely high concentrates of EPA, DHA, DPA and other specific Omega-3s. Additionally, this technology can be used for chiral separations of small molecule APIs and KD Pharma is one of the only companies in the world with both pilot and production scale capabilities.